Call: 08045812922

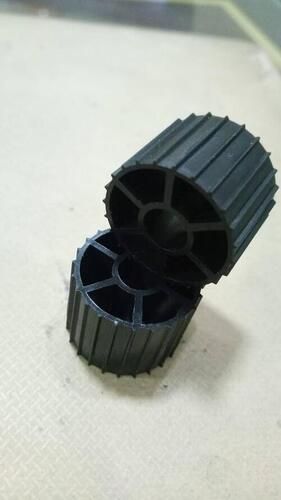

Water Treatment MBBR Media

Price 7000.0 INR/ Piece

MOQ : 1 Piece

Water Treatment MBBR Media Specification

- Recycle Rate

- 80-90%

- Pump Type

- Centrifugal/Submersible

- Usage & Applications

- Biological wastewater treatment, Sewage/ETP/STP systems

- Technology

- Biofilm Reactor

- Frequency

- 50 Hz Hertz (HZ)

- Efficiency (%)

- 85-95%

- Ph Level

- 6.5-8.5

- Power Consumption

- 0.2-1.5 kW Kilowatt (kW)

- Flow Rate

- 5000-50,000 L/hr

- Water in conductivity

- 500-1500 S/cm

- Water Out Conductivity

- <20 S/cm

- Feature

- UV Stabilized, High Durability, Long Life

- Noise Level

- <60 dB db

- Drive Type

- Rotational/Fixed

- Power Source

- Electric

- Water Source

- Industrial & Municipal Wastewater

- Automatic Grade

- Semi-Automatic

- Product Type

- Moving Bed Biofilm Reactor (MBBR) Media

- Material

- Virgin Polypropylene (PP)

- Purity Level

- 98%

- Voltage

- 220V Volt (v)

- Filter Type

- Biological/Media Filter

- Installation Type

- Modular

Water Treatment MBBR Media Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Domestic Market

- All India

- Certifications

- Technical specification and test certificate available.

About Water Treatment MBBR Media

Owing to our ethical business policies, we have been successfully indulged in offering Water Treatment MBBR Media. The offered media is widely used to support the growth of heterotrophic and autotrophic bacteria within its cells. This media is manufactured under the vigilance of our diligent professionals using the finest quality raw materials with the aid of modern techniques. Furthermore, the provided Water Treatment MBBR Media can be bought from us in several specifications at economical prices.

Features:

- Compact size

- Perfect finish

- Easy to fit

- Highly durable

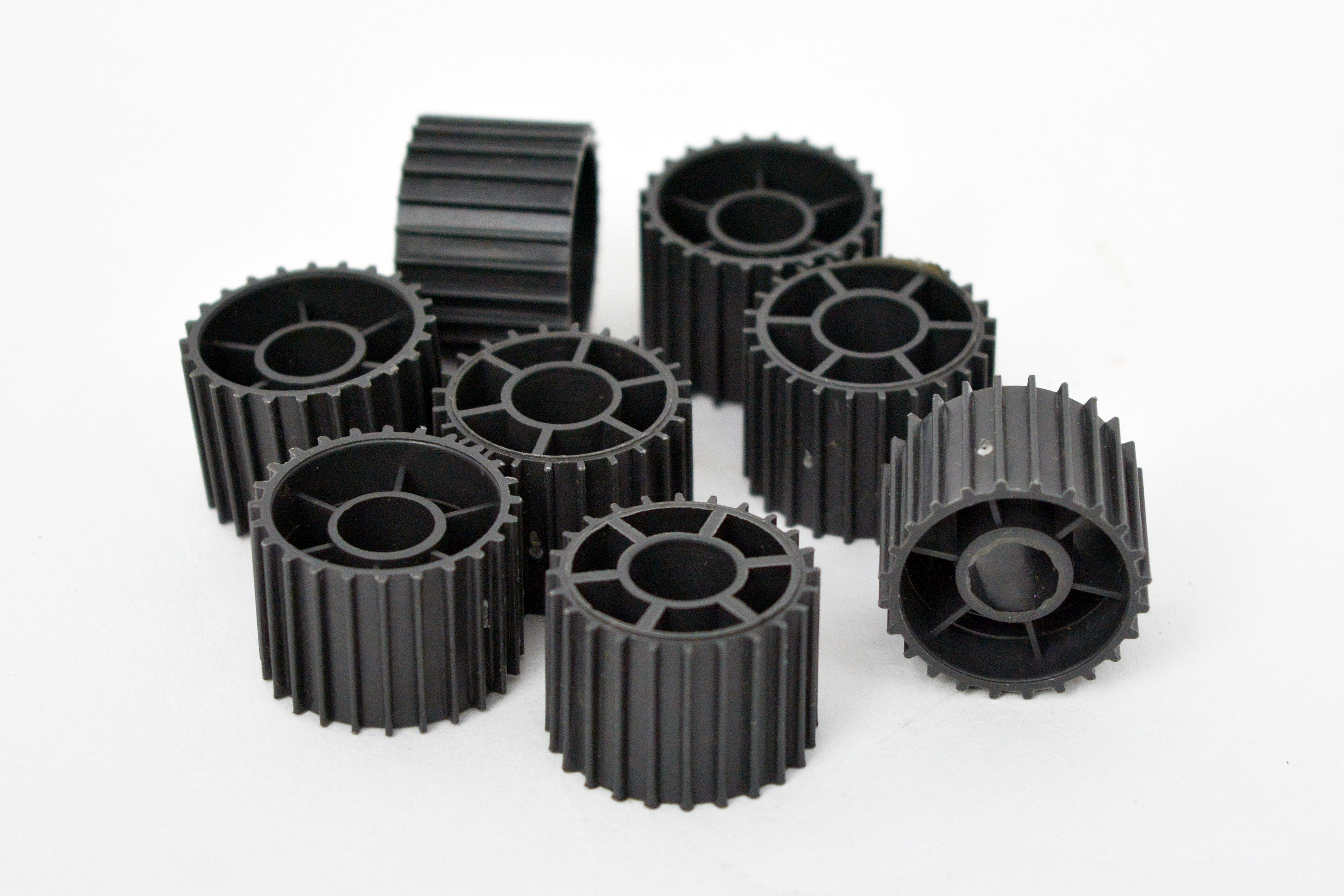

Efficient Biofilm Technology for Wastewater Treatment

Utilizing advanced K1, K3, K5, and tube/wheel designs, our MBBR media enhances biofilm formation for superior decomposition of organic pollutants. The high surface area and modular packing increase microbial activity and treatment efficiency, resulting in cleaner effluent with conductivity as low as <20 S/cm, compliant with rigorous discharge standards.

Durable and Safe Construction

Manufactured from food-grade, virgin polypropylene, our media offers excellent chemical and corrosion resistance for reliable operation across diverse water conditions. The non-toxic and UV-stabilized design ensures longevity and environmental compatibility, while RoHS compliance adds assurance of material safety for both users and ecosystems.

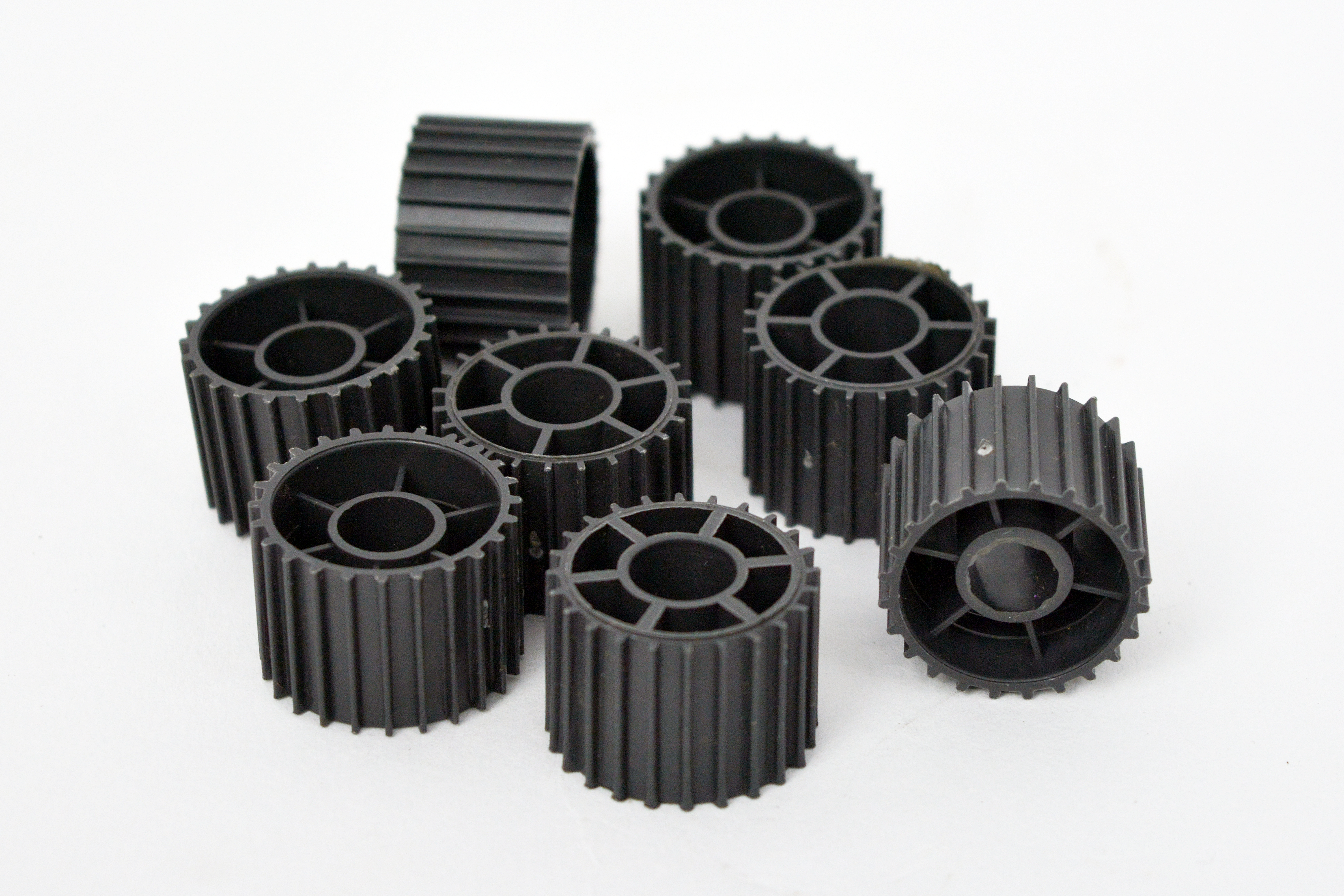

Flexible and Scalable Solutions

Available in multiple shapes and customizable volumes, our MBBR media suits a wide range of flow rates (5,00050,000 L/hr) and capacities (50,000500,000 L/day). Theyre ideal for new installations and retrofits in sewage, ETP, or STP systems. Easy modular deployment simplifies system expansion or maintenance, letting users optimize treatment with minimal operational downtime.

FAQs of Water Treatment MBBR Media:

Q: How does cylindrical MBBR media improve biological wastewater treatment?

A: The cylindrical MBBR media, with internal fins and large surface area, supports robust biofilm growth, accelerating the breakdown of organic matter in wastewater. This leads to higher treatment efficiency (8595%) and improved effluent quality for both industrial and municipal applications.Q: What are the typical applications of this MBBR media?

A: This media is widely used for sewage treatment plants (STP), effluent treatment plants (ETP), and biological filters in industrial and municipal wastewater treatment. Its suitable for systems requiring high purity and efficient organic contaminant removal.Q: When should I replace the MBBR media during system operation?

A: With a lifespan of 810 years under normal operational conditions, replacement is generally only required after this period or if there is significant mechanical damage. The medias high durability and chemical resistance minimize frequent replacement needs.Q: Where can I install this MBBR media in my treatment process?

A: The media is designed for modular installation in aeration tanks or dedicated biofilm reactors of ETP, STP, or industrial wastewater systems. It accommodates both new setups and retrofits, fitting a variety of tank sizes and process configurations.Q: What is the installation process for this MBBR media?

A: The media is typically supplied in HDPE bags or in bulk and requires simple distribution into the designated treatment chambers. No adhesives or complex equipment are needed, and the modular design allows quick adaptation to system requirements.Q: How does the MBBR media benefit long-term operations?

A: Thanks to low maintenance requirements, a lifespan of up to 10 years, and high recycle rates (8090%), the media ensures sustainable, cost-effective wastewater treatment. It also achieves a high purification level of up to 98% while keeping operational noise and energy consumption low.Q: What safety and quality standards does the MBBR media comply with?

A: The media is manufactured from food-grade, virgin polypropylene, and is certified as non-toxic, RoHS compliant, and UV stabilized, ensuring safety for users and the treated environment. It is suitable for both potable water-related and industrial systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry